Surface Mount PCB Assembly

On-board engineering ability applied to your PCB assembly

Phase One Electronics have invested heavily in the Juki suite of modular placement systems. Their reliability and accuracy ensures consistent results and fault free operation. We can place all types of components from 0201 through to micro BGA’s. We offer a cost effective solution to any SMT requirement.

Supported by DEK screen printing technology with camera alignment for exact XY positioning and DIMA’s hot air forced convection soldering system with independently microprocessor controlled heating zones, uniform heating and thus consistent results are achieved.

Because of our understanding of the need for the total reliability of your products we put an immense importance on process control. From component and board storage prior to use and the environment in which the product is built right through to the equipment we use we ensure total control and reliability.

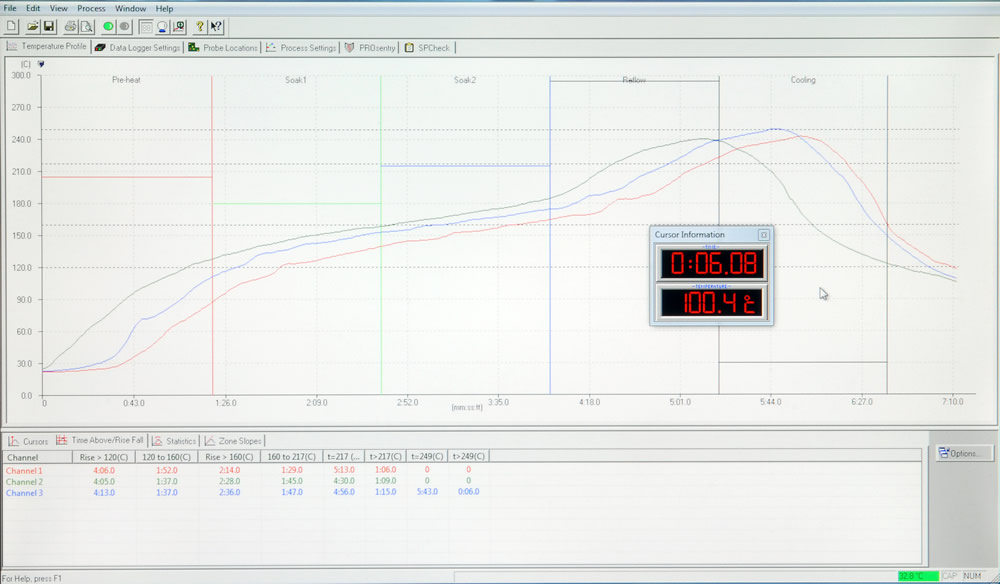

All PCBs are profiled to ensure that they are correctly soldered and that critical temperatures and dwell times are achieved. Records are kept of all profiles for individual board types to ensure customer confidence and repeatability on future batches. Dry storage and baking of devices and boards is undertaken to ensure optimum moisture control prior to use.

Gerber information is reviewed prior to screen manufacture to ensure that optimum results are obtained.

Surface Mount Capabilities

- Juki modular placement systems

- DEK Screen Printing

- DIMA Forced Air Convection reflow

- Moisture Control

- Climate Controlled environment

- Critical Profiling

- Screen management

Correct board profiling for optimum results